BA30 Rear Wheel

The BA30 is a quality alloy rim designed to withstand a real beating.

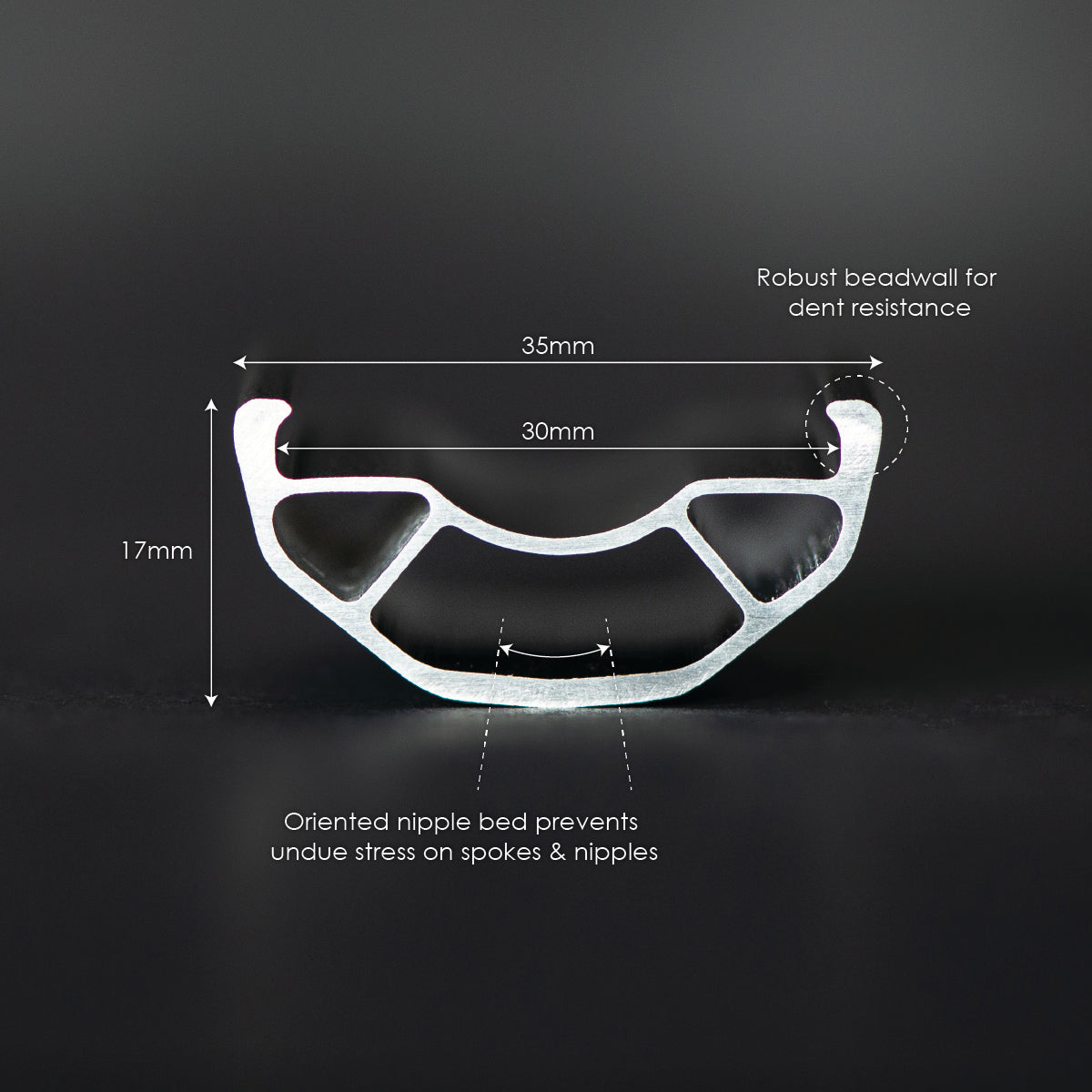

This is the rim for high-impact riding when the trails are rough and rugged. With an internal bracing structure, the BA30 has torsional stiffness for directional control in demanding circumstances. The BA30 features a thick bead wall adjacent the tire to resist impact deformation, with a wider, rounded top-edge to reduce sidewall cuts. The nipple/spoke bed is oriented to the spoke direction to reduce weakness caused by bend in the spoke at the nipple hole. The BA30 is made with premium alloy, extruded with an internal brace profile and carefully formed for consistent shape. It is then fusion welded and ground for a strong precise finish. Our fusion welding system leaves a perfect seamless joint that becomes the strongest section of the rim ensuring that your rim won’t split if you impact at the seam.

The rims are laced to our new R4 hub. The R4 is designed to be a solid, reliable hub with a durable axle assembly and robust set of bearings. We're using a tried and tested 4-pawl arrangement with 36 points of simultaneous engagement. What sets it apart is the large radius that the pawls are positioned on, reducing leverage at the point of engagement.

We opted for a Chromoly steel axle for stiffness and longevity. Using steel allows a smaller diameter axle which in turn gives us more room to use larger, sealed bearings (we use USA made enduro bearings). The rear axle assembly uses thread-on end caps which are easy to service and resist compression from the frames axle (they don’t fall off during trailside repairs either!). R4 front hubs are available with standard or ‘torque’ end caps and rear hubs are available with XD, HG, or Microspline drivers. We supply all parts for servicing to ensure that R4 hubs can be maintained well into the future!

Use code: WheelieGood to receive $50 off when you buy a front and rear wheel.

Hub Specs

Axle Diameter // 12mm

Spacing // Boost 148mm

Driver // XD, HG or Microspline

Engagement// 4-Pawl, 36 Point

Spokes // 32

Disc Mount // 6 Bolt

key features

Design Considerations

Wheel FAQ's

Our wheels are pre-stressed and ready to ride out of the box. We also use Nylock spokes to keep the tension where it should be. We've found this to last longer and stay in place better when adjustments are made later on.

However, like all wheels there is a bedding-in period, so be sure to keep an eye on spoke tension after the first few rides.

Because the bike industry likes to invent new standards by the hour, there are different freehubs to choose from depending on which cassette you run.

HG is typically for older drivetrains and SRAM NX.

XD is for newer SRAM.

Microspline is for newer Shimano.

The R4 is compatible with HG, XD & Microspline, so if you do decide to change your drivetrain, all you need to do is switch out your freehub.

Wheels come pre-taped with tubeless valves installed.

All you need to do is install tires and sealant.

If you got our wheels on a complete bike from us, tires and sealant will already be installed and seated, just inflate to desired pressure.

Provided the rim does not have a crack, you can use an adjustable wrench to gently bend it back to help your tyres seat properly. (One of the benefits of alloy over carbon)

Use a rag or an old inner tube to prevent scratching your rim, and be careful to avoid puncturing your rim tape!

You'll likely need to adjust spoke tension if your wheel has taken a hit hard enough to dent it.

Having fewer points of engagement leads to more backlash in the system, this is apparent predominantly in climbing gears and technical situations. That being said, from our experience you very quickly become accustomed to the hub you are running and it rarely crosses your mind when riding after the first ride of a new component.

The more points of engagement, the smaller the area of contact between pawls and ratchet ring, along with fewer pawls engaging at the same time. This is in order to fit more into the same space, often leading to reliability issues especially as parts start to wear.

With the R4 we have tried to strike the happy middle ground of having enough points of engagement to feel sharp but also leave room for long term reliability.

Of course there is also the topic of pedal kick back and suspension interaction, which could be a full article in itself.

To keep things simple, a higher engagement hub has the potential to give more feedback due to less backlash before it engages. In general, we think there are a myriad of more important things to worry about in how a bike rides.

If you notice any play in your wheel when your axle is tight its time to check things out. Similarly if you can hear or feel the bearings grumble when spinning, an investigation and likely fresh set of bearings would be a good move.

If you are doing a pre-season refresh or just giving your bike a thorough going over then cleaning and re greasing your freehub body is a good move, removing any contaminants and adding fresh clean grease is a good way to reduce long term wear.

They both use our top end alloy with a fusion welded seam-ground join, and have a 30mm inner width.The main difference is the BA30 has some extra internal bracing, making it stronger and a bit heavier.If you're really on the fence, run a Phase on the front and BA on the rear.

The Phase and BA are fusion welded, and post ground which makes the join the strongest part of the rim!The Ally is pinned at the joint, which is more simple and less labour intensive, but not as strong. The Ally is also slightly heavier as the alloy used has slightly less strength than that of the BA and Phase.